Understanding a High And Low Pressure Switch Wiring Diagram is crucial for anyone working with refrigeration, air conditioning, or industrial fluid systems. These diagrams provide a roadmap, illustrating how these essential safety and control devices are connected to the rest of the system, ensuring efficient and safe operation. A clear High And Low Pressure Switch Wiring Diagram helps technicians diagnose problems, perform maintenance, and install new equipment with confidence.

What is a High And Low Pressure Switch Wiring Diagram and How It Works

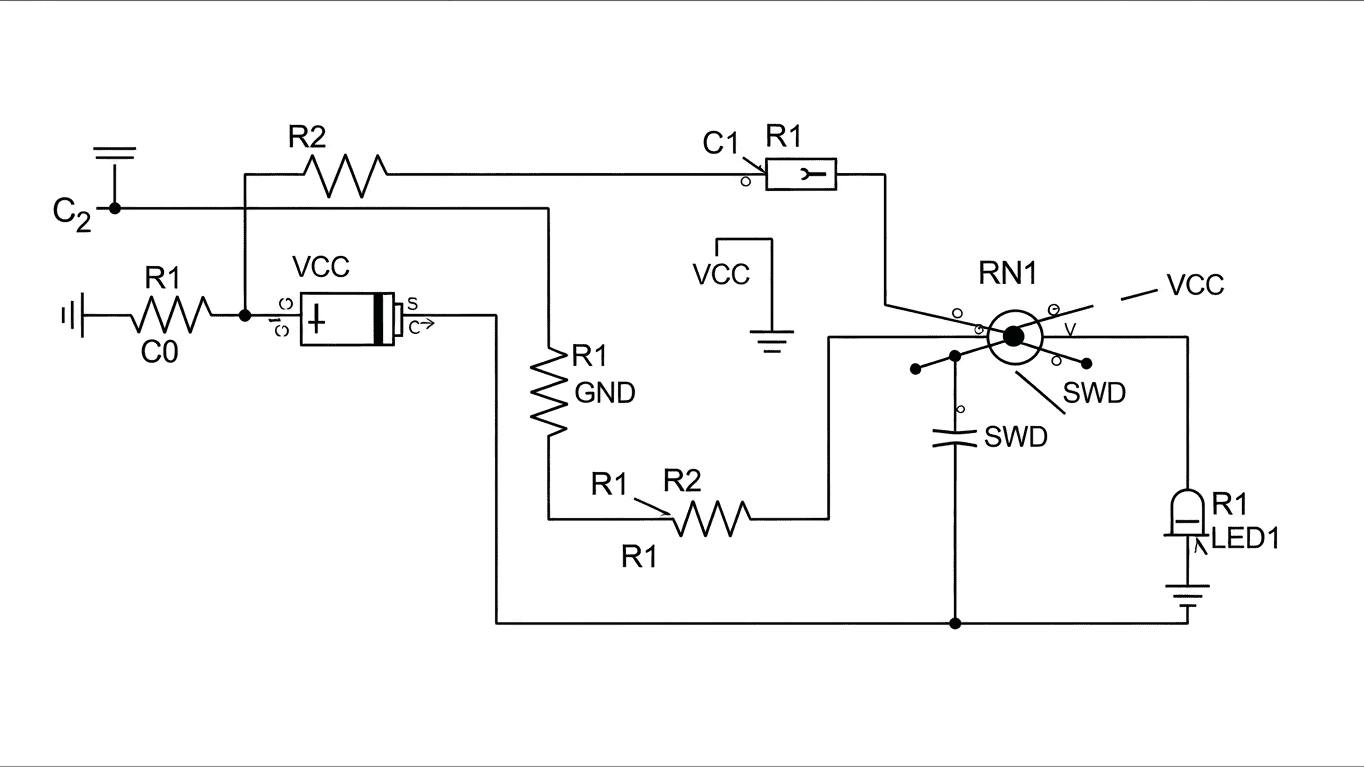

A High And Low Pressure Switch Wiring Diagram is a schematic that details the electrical connections between pressure switches and other components in a system, such as compressors, contactors, and control boards. Pressure switches are safety devices designed to protect equipment from damage caused by operating outside of safe pressure ranges. For instance, a low-pressure switch prevents a compressor from running when the refrigerant pressure drops too low, which could lead to its failure. A high-pressure switch, conversely, will shut down the system if the pressure rises too high, preventing catastrophic damage to components like the compressor or piping.

These switches typically have two or three terminals. A common configuration involves a normally closed (NC) contact and a normally open (NO) contact. In a typical system, the low-pressure switch is wired in series with the control circuit that energizes the compressor contactor. If the low-side pressure falls below the set point, the NC contacts will open, breaking the circuit and stopping the compressor. The high-pressure switch is also usually wired in series with the compressor control circuit. If the high-side pressure exceeds its set point, its NC contacts will open, interrupting power to the compressor. Some systems may also utilize NO contacts for different control functions, such as activating a fan when a certain pressure is reached.

The information presented in a High And Low Pressure Switch Wiring Diagram can vary depending on the complexity of the system. However, essential elements usually include:

- Symbols for pressure switches (often depicted as a diaphragm with contacts).

- Symbols for other components like contactors, relays, and the compressor.

- Lines representing wires, with clear indications of connections.

- Terminal designations for each component.

| Component | Terminal 1 | Terminal 2 | Function |

|---|---|---|---|

| Low Pressure Switch | Control Power In | Control Power Out (to Contactor Coil) | Opens circuit if low pressure is detected. |

| High Pressure Switch | Control Power In | Control Power Out (to Contactor Coil) | Opens circuit if high pressure is detected. |

To get the most precise and applicable information for your specific needs, please refer to the detailed High And Low Pressure Switch Wiring Diagram provided by the equipment manufacturer. This will ensure you are working with the exact configuration for your system.