The Honeywell Equipment Interface Module Wiring Diagram is an essential document for anyone working with HVAC systems, building automation, or industrial controls. It provides a visual guide that outlines how various electrical components connect to a Honeywell Equipment Interface Module (EIM). Understanding this diagram is crucial for proper installation, troubleshooting, and maintenance of complex equipment.

What is a Honeywell Equipment Interface Module Wiring Diagram and How is it Used?

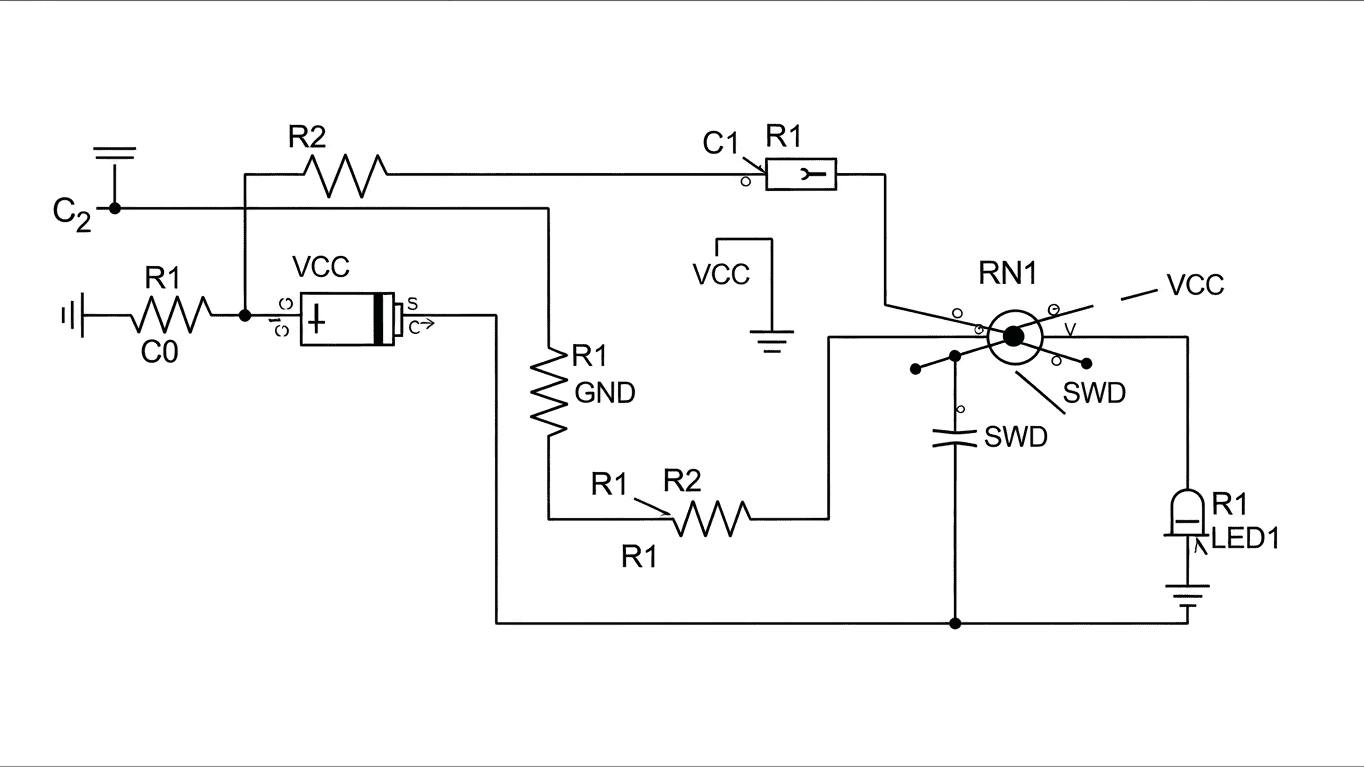

A Honeywell Equipment Interface Module Wiring Diagram is a schematic that illustrates the precise electrical connections between an EIM and other devices within a system. These EIMs act as translators, allowing different pieces of equipment, often with varying communication protocols or voltage requirements, to work together seamlessly. The diagram details the terminals on the EIM and specifies which wires from sensors, actuators, power supplies, and control panels should be connected to each terminal. This clarity is paramount for ensuring the system functions correctly and safely.

These diagrams are indispensable tools for a range of professionals. Technicians rely on them to install new systems, ensuring that every connection is made according to manufacturer specifications. When a system experiences issues, the wiring diagram becomes a roadmap for diagnosing problems. By tracing the connections, one can identify faulty components, loose wires, or incorrect wiring that might be causing malfunctions. The EIM itself can have several types of connections, including:

- Digital inputs for status signals (e.g., on/off, fault)

- Analog inputs for sensor readings (e.g., temperature, pressure)

- Digital outputs for controlling devices (e.g., relays, fans)

- Communication ports for network connectivity

The use of a Honeywell Equipment Interface Module Wiring Diagram typically involves a systematic approach. A technician will:

- Identify the specific EIM model being used.

- Locate the corresponding wiring diagram for that model.

- Refer to the diagram to understand the function of each terminal on the EIM.

- Connect the appropriate wires from external devices to the designated terminals on the EIM.

- Verify all connections against the diagram before powering up the system.

For more complex setups, the diagram might also include a table outlining the expected voltage levels or signal types for each connection. For instance, a table might look like this:

| EIM Terminal | Connected Device | Expected Signal |

|---|---|---|

| AI1 | Temperature Sensor | 0-10V DC |

| DO1 | Fan Relay | 24V AC |

To successfully implement or troubleshoot your Honeywell system, consult the specific Honeywell Equipment Interface Module Wiring Diagram provided by the equipment manufacturer or available through your authorized Honeywell distributor.